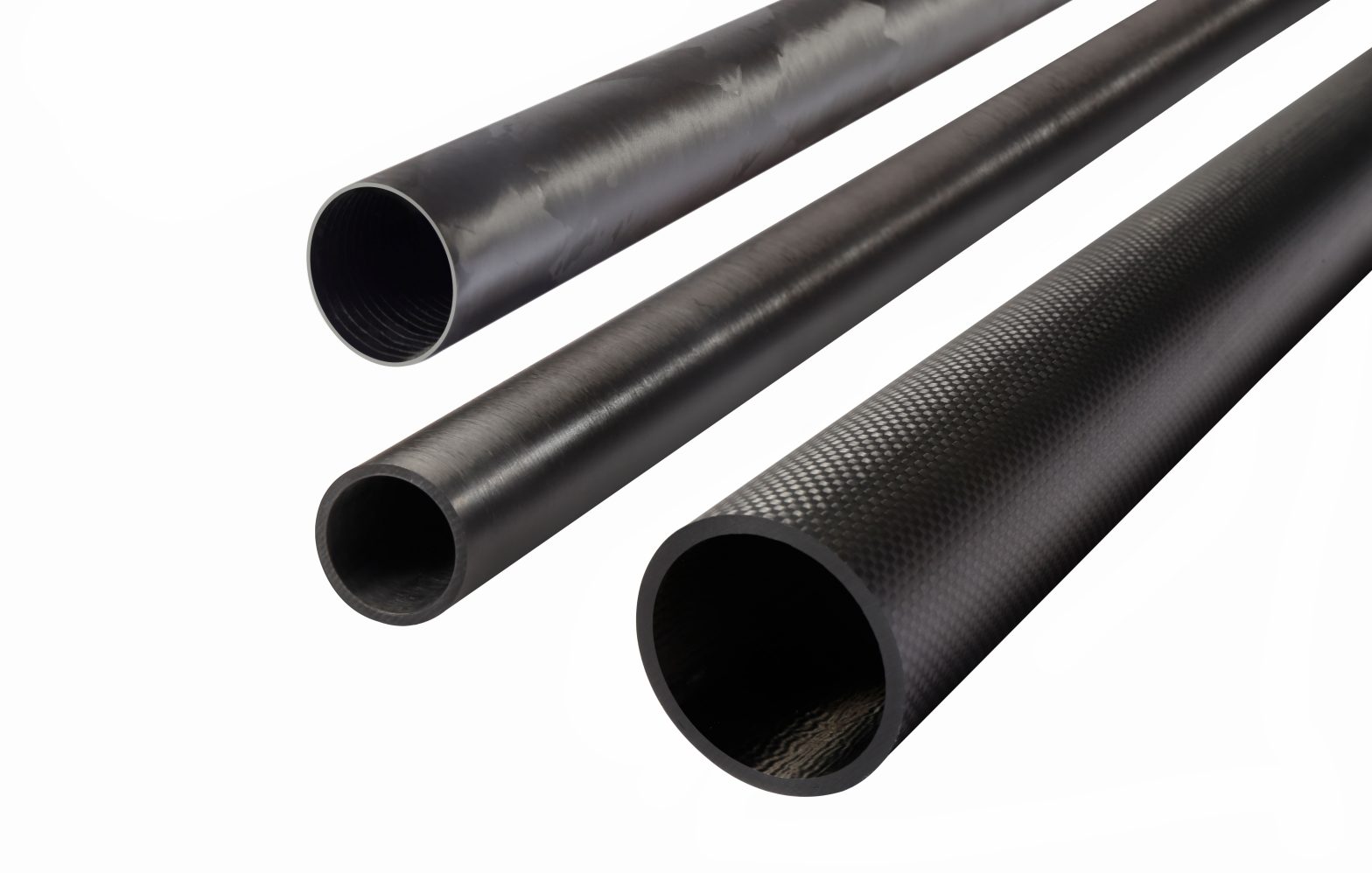

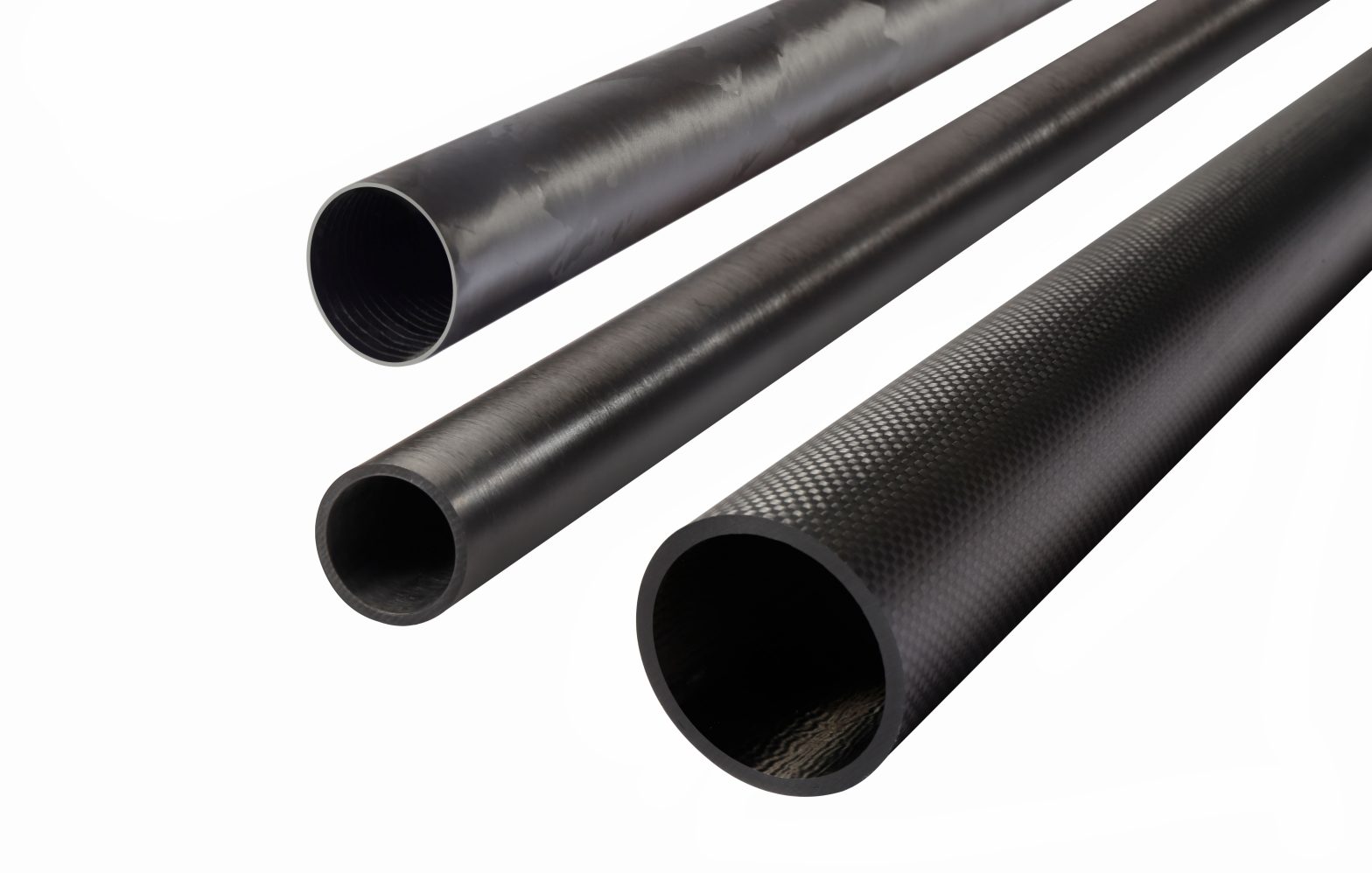

Carbon fiber tubes are quickly taking the lead as a top choice in today’s engineering and design environment, where success is determined by factors like performance, weight, and durability. These tubes, which are used in a wide range of industries from robotics and sports equipment to automotive and aerospace, are renowned for their exceptional strength-to-weight ratio and visual appeal. TipTop Composites, a manufacturer of custom carbon fiber tubes and pipes renowned for its skilfully designed, high-performance composite solutions, is at the vanguard of this revolution.

Precision-Crafted Carbon Fiber Tubes for Every Application

TipTop Composites provides a large selection of custom carbon fiber tubes that are made to match each customer’s precise requirements. Whether it’s for an aerospace-grade component, a lightweight structural frame, or a drone arm prototype, TipTop Composites can design and produce:

- Carbon fiber tubes can be square, rectangular, oval, hexagonal, tapered, or even octagonal.

- Filament-wound, roll-wrapped, and pultruded options are available to meet different structural and load-bearing requirements.

- Carbon Kevlar hybrid tubes to improve resistance to impacts

- Flexible stiffness and performance are offered by high modulus, intermediate modulus, and standard modulus tubes.

Additionally, clients can select fiber weaves (unidirectional, twill, and plain), surface finishes (glossy, matte, and textured), and custom machining services for parts that are ready to install. All of these options make TipTop Composites a go-to for bespoke composite tube solutions.

Advanced Manufacturing Technologies for Superior Results

Modern composite manufacturing techniques are used by TipTop Composites to produce reliable, superior results:

- Roll-wrapping: Ideal for thin-wall, high-precision tubes, it provides exceptional dimensional accuracy and aesthetic quality.

- Filament winding: It is perfect for long-distance applications like pipes, poles, or shafts that need directional strength.

- Pultrusion: It’s an economical technique for creating large quantities of straight-length tubes with superior mechanical qualities.

- Custom Tapering and CNC Machining: Enabling perfect fitting, drilling, sanding, and printing for final-use components.

As a result, TipTop Composites has a wide range of manufacturing capabilities that enable it to meet the demands of various and intricate industries.

Complete End-to-End Composite Solutions

TipTop Composites offers comprehensive project solutions in addition to producing carbon fiber tubes. From idea to finished product, the business provides:

- Engineering design support: Working closely with customers on structural analysis, CAD modelling, and specifications

- Prototyping and tooling: Ideal for R&D departments and product developers seeking quick iteration cycles

- Custom assembly and finishing services: Including painting, bonding, and surface treatment

- Quality assurance: Thorough testing, tolerance checks, and documentation at each step

Customers are guaranteed a fully optimized and production-ready composite solution thanks to this integrated approach.

Key Advantages of Carbon Fiber Tubes

Why are carbon fiber tubes becoming more and more popular among engineers and manufacturers over metal ones?

Outstanding Strength-to-Weight Ratio: Much lighter than steel but up to five times stronger

- Corrosion Resistance: Ideal for outdoor and marine applications

- Design flexibility: Allows for customization, shaping, and tapering with little loss of structural integrity.

- Thermal Stability: Low thermal expansion, perfect for precision parts

Because of these characteristics, TipTop Composites’ carbon fiber tubes are essential in fields such as industrial automation, defense systems, performance cycling, space technology, and unmanned aerial vehicles.

Conclusion

Strong, lightweight, and adaptable materials are becoming more and more in demand as industries push the limits of innovation. In addition to being strong and long-lasting, TipTop Composites‘ carbon fiber tubes are made with customization and application flexibility in mind. They are a strategic partner in any composite material project because of their full-spectrum service model, which covers design, production, and delivery.